Scalable. Smart. Sustainable Automation for the Future of Tobacco Manufacturing

At Quad, we empower traditional tobacco manufacturers and new-age nicotine product companies with end-to-end automation—from green leaf processing to final pack-out. Whether you're producing combustible cigarettes, heated tobacco sticks, nicotine pouches, or e-cigarette devices, Quad delivers integrated, efficient, and reliable solutions across processing, making, filling, packing, and flow automation.

A solution for entire tobacco value chain

Our expertise spans the entire tobacco production value chain, offering intelligent systems for making, filling, assembling, packing, and end-of-line handling—ensuring maximum efficiency, precision, and compliance.

- Affordable solutions for aligning, inserting, and sealing components

- Entry-level automation for NGP startups

- Retrofitting legacy equipment

- Labelling and Coding Modules

- Visual Inspection Systems (Camera Modules) for QC

Tobacco Processing Automation

Quad’s cutting-edge tobacco processing solutions streamline every stage of raw material handling and conditioning to ensure consistency, flavor retention, and throughput optimization.

Cutting & Coating

- Roll-to-Roll Processing

- Tobacco Strip Cutting & Slicing

- Electrode, Extrusion & Solution Coating – supporting advanced NGP material applications

Drying, Conditioning & Flavoring

- Casing and Flavor Dosing Systems

- Stem Flattening, Toasting & Expansion Dryers

- Reconstitution Processing Units

- Conditioning Tunnels for Moisture Control

Storing & Feeding

- Intermediate Storage Silos

- Automated Feeding and Dosing Systems

- Green Leaf Threshing (GLT) Technology

Air Treatment & Exhaust Systems

- Dry & Wet Exhaust Management

- Air Filtration and Cleaning for Tobacco Environments

Primary Processing for NGPs

- NGP Primary Material Handling & Conditioning

- Powder Treatment & Cosmetic Powder Drying for modern oral formats like Snus, Nicotine Pouches, and Molasses-based products

Smart Flow Automation

- Bale Handling & Undressing

- Conveyor & Transfer Systems for Leaf and Cut Rag

- Software-Based Line Control & Monitoring Systems

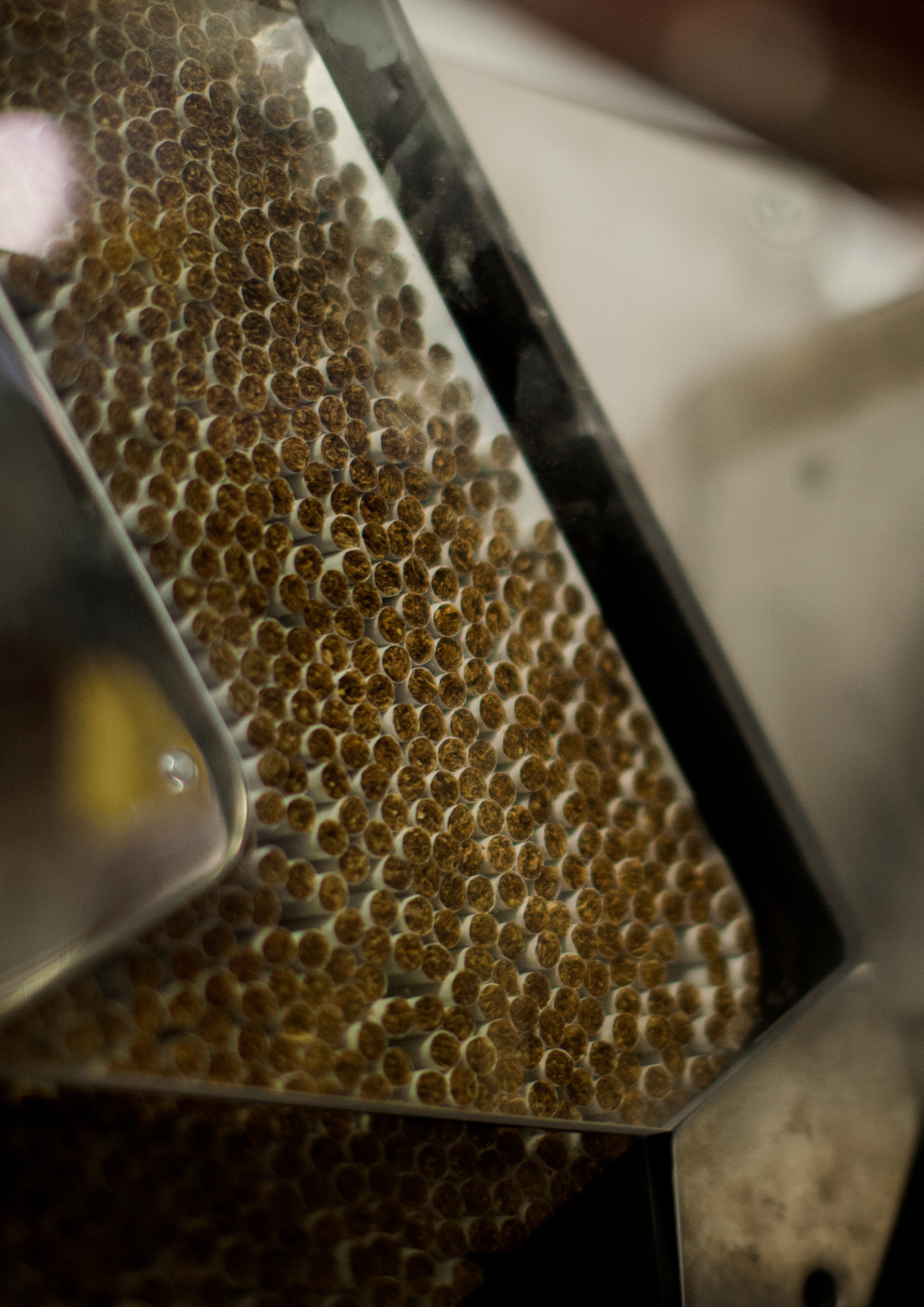

Tobacco & Cigarette Manufacturing Automation

Assembly & Combining

- Cartridge Assembly for E-cigarettes

- Combiner for Multi-segment Filters & HNB Devices

Flow Automation

- Tray Handling Systems

- Line Balancing & Buffering Units

Filling Solutions

- High-Precision E-Liquid Filling Machines

- Suitable for closed pods, cartridges, and bottled liquids

Making & Forming

- Cigarette Rod Making & Filter Rod Making

- Electrode Stacking & Winding for Heated Tobacco Units

Packing, Wrapping & End-of-Line Automation

Quad offers a complete suite of secondary packaging and wrapping systems tailored to tobacco’s regulatory, branding, and speed demands.

Packing & Wrapping

- Cigarette Packing, Fold Wrapping, Flow Packing

- Stamp and Coupon Application for Duty-Free and Local Markets

Pouching & Bagging

- Horizontal Flat Pouching Machines for NGP, chewables, or molasses-based formats

Cartoning & End-of-Line

- Carton Erecting, Box Filling & Sleeve Wrapping

- Case Packing & Palletizing with Integrated Traceability

Smart Controls & Compliance

Our systems are fully integrated with real-time line monitoring, data analytics, and production reporting to ensure traceability, regulatory compliance, and line efficiency—especially critical in tightly regulated markets like tobacco and nicotine.

Industries Served:

- Traditional Tobacco (Cut Rag, Strips & Stems)

- Heated Tobacco (Heat-Not-Burn)

- Modern Oral (Snus, Nicotine Pouches, Molasses)

- E-Cigarettes & Vaping

- Personal Care, Cosmetics & Pharmaceuticals (for shared processing tech)

- Battery Cells & Optical Materials (Electrode processing crossover)

- Packaging Material & Industrial Goods